Our Range of Services

Industrial Solutions for Automation & Digitisation

Consulting and Planning

Since two decades LEiTEK is planning…

… the automation of complex plants. Furthermore, we carry out retrofitting of already existing plants.

We are glad to consult on how to optimise your plant, your process control as well as your data management.

Together with you we check the technical status of your plant on-site, discuss the technical requirements and determine the needs.

Additionally we define the exact task with you.

When all details are clarified and you have chosen a solution, we submit you a detailed offer based on the mutual requirement’s specification.

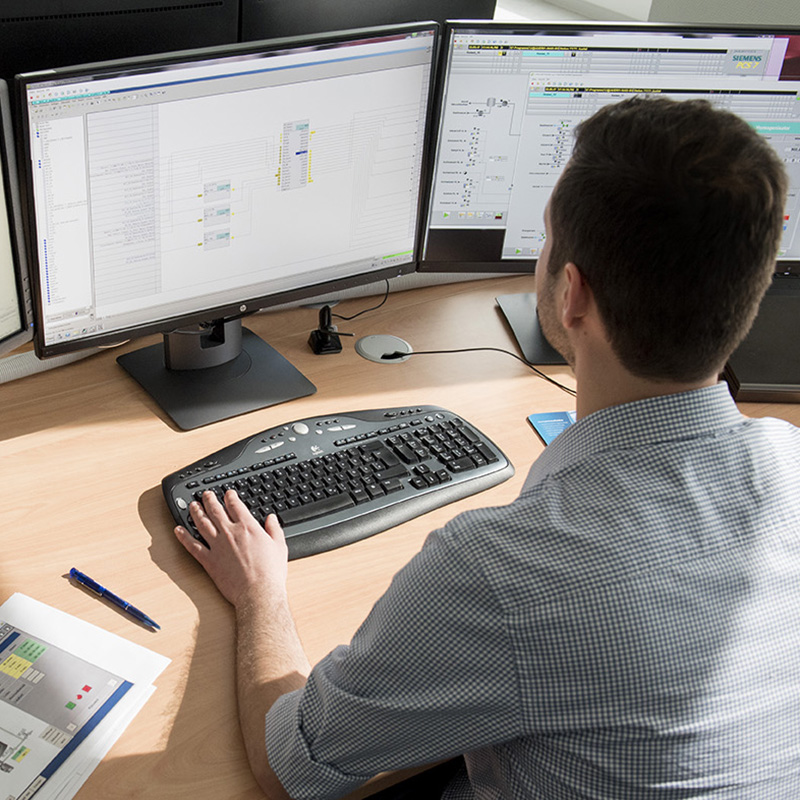

Software Solutions for Automation

Being a certified Siemens Solution Partner…

… we would be happy to carry out the complete project planning and programming of your automation software. Therefore, we use various Siemens automation tools, e.g. Simatic Step 7, TIA Portal or PCS7.

Our software solutions are precisely adapted to the specific features of your plant and are available in German or English. All process visualisations meet your individual requirements. This is also true for the user interfaces which can be programmed in different languages.

At an initial installation we would be glad to advice you on the expansion of functionalities. Furthermore, we carry out retrofitting of already existing plant software.

Our experienced automation team also realises parameterizations of drive modules, tests already existing software, creates logic diagrams or test specifications and carries out process simulations.

Once the project has been completed, we provide the corresponding documentation in German or English.

Basic and Detailed Projekt Planning

Our in-house hardware planning…

uses the project planning software EPLAN all the necessary to create all the necessary electrotechnical planning documents such as circuit diagrams, Input/Output lists, parts lists and so on.

Futhermore our experienced team develops test specifications for your switching systems and carries out the final acceptance test as well as the quality control.

Our range of services also includes to supply and install all electrical componets, which are necessary for the implementation.

Once the project has been completed, we provide you with the corresponding documentation in German or English.

IT-Solutions

Customised Software Applications

For you our in-house IT department develops software applications for PC and database systems to allow a process-oriented evaluation of quality, production and energy management data.

Therefore, LEiTEK uses the software development environment MS.NET as well as the database environment MS SQL. For process visualisations we use Development Express Library Functions (Single-User or Server Client Solution).

Process data from different control systems can be collected by means of standardised methods (e.g. OPC).

Process Simulation

By using the Siemens Simulation Software Simatic Simit

You can test all the relevant automation functions as well as possible occurring facility malfunctions in advance.

This will enable us to carry out together further optimisations at no extra costs due to facility shut down .

With this software we also be able to train your operation personnel under realistic conditions. The participants will consequently control a virtual plant only, but with all the original operation pictures and automation programmes.

Switch Cabinet Construction & Assembling

Our team

Manufactures customised switch cabinets (for interior and exterior use) for automation and drive engineering as well as low-voltage switchgears while following national and international regulations for customers all over the world.

Furthermore, we design and construct fixtures and customised switchboards, e.g. with changed dimensions climatized or in custom paintwork.

Our range of services includes the electrical planning, the entire manufacturing process, the error diagnostics and troubleshooting as well as the complete installation and function tests on-site.

Commissioning and Optimisation

Factory Acceptance Test

Prior to commissioning, we will invite you to a Factory Acceptance Test to review our solutions under realistic conditions and – if necessary or desired – identify optimisation needs.

Once completed, all components will be installed on-site and finaly tested again.

Training, Maintenance and Services

We will be pleased to assist you furthermore…

… even when the projects have already been successfully completed.

We train and prepare your staff on the optimised use and operation of the installed soft- and hardware.

Additionally, we carry out maintenance services (even remote maintenance) and take care for appropriate spare parts.

Our range of services also comprises the Profibus-Diagnose during operation

If required, please also ask for the inspection of mobile and fixed equipment/ facilities according to DIN VDE 0701-0702 and DGUV/Regulation 3.